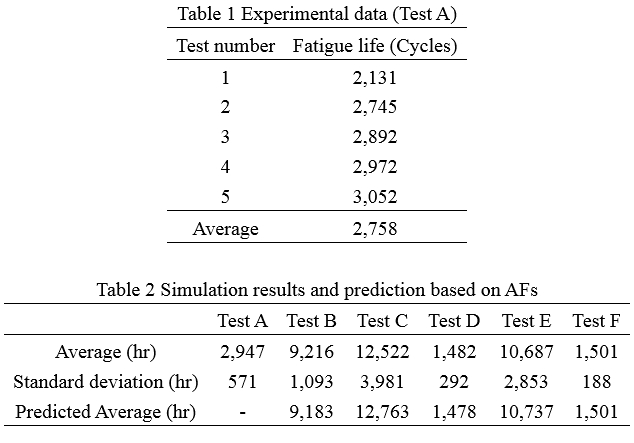

In the semiconductor industry, the study of reliability and the ability to predict temperature cycling fatigue life of electronic packaging are of significance. For that purpose, researchers and engineers frequently employ the finite element method (FEM) in their analyses. It is primarily a mechanics analysis tool that takes material properties, manufacturing processes and environmental factors into consideration. Engineers also like to use FEM in their design of electronic package, but frequently the term “reliability” they refer to only addresses the robustness of a particular design. It has little to do with probability and statistics. Meanwhile, in manufacturing factories of electronic products, including packaging, accelerated life testing (ALT) is carried out very often by quality engineers to find lives of a product in severe environmental conditions more than that of the field condition. Through regression analysis of the test result based on an empirical or semi-empirical formula, the acceleration factor (AF) can be obtained for use in predicting service life of the product in field condition. Again, other than regression analysis, little probability and statistics are involved. By taking parameter uncertainties into consideration, this article demonstrates by an example that FEM, ALT and AF can be combined to study the reliability of electronic packaging in which probability and statistics are applied. (吳文方教授提供 wfwu@ntu.edu.tw)

Figure 1 A package for illustration